When the Kenworth K270e was announced in 220 I was interested. For my application I need cabovers, specifically in the 26k GVW size. This was also before I had purchased any electric trucks (or even driven one), so it was a truck I might potentially buy.

Reservations?

I had looked into the K270 with the Cummins engine in a previous truck purchasing iteration. I ended up waiting for the Isuzu FTR and leasing that. I had inquired about purchasing an off-lease K270 that matched my desired spec, but saw in the listings that it had been owned by a lumber yard and I could read which one. So, I just called them to ask how the truck had been. They didn’t like it. Why? Reliability: It had gone down for months for a headlight that was out and the dealership couldn’t figure it out. Sounds crazy right? Well, many modern trucks are total contraptions with a separate computer in each component and a complicated wiring harness to match. What compounded this was that the truck was actually a European truck and NOT designed by Kenworth. In [{insert}, Kenworth bought/merged with DAF which is a German company. DAF has a very long history, being one of the original companies to lease the Diesel design from Rudolph Diesel himself. I suspect DAF makes a perfectly good truck but the issue here is that it was wholly unfamiliar to North American mechanics. At any rate, I passed on that truck but what I learned from that informed my initial opinion of the K270e. Maybe things had gotten better, but I still didn’t see many diesel K270s on the road, and it was a significant data point.

Pricing back in 2021

I called up a few local dealerships and finally got someone interested in the idea. They got me a quote. For the 141kwh battery, the price was $394K and for the 282kwh battery the price was $542K. I took this to indicate they didn’t really want to sell the truck but were only manufacturing press releases.

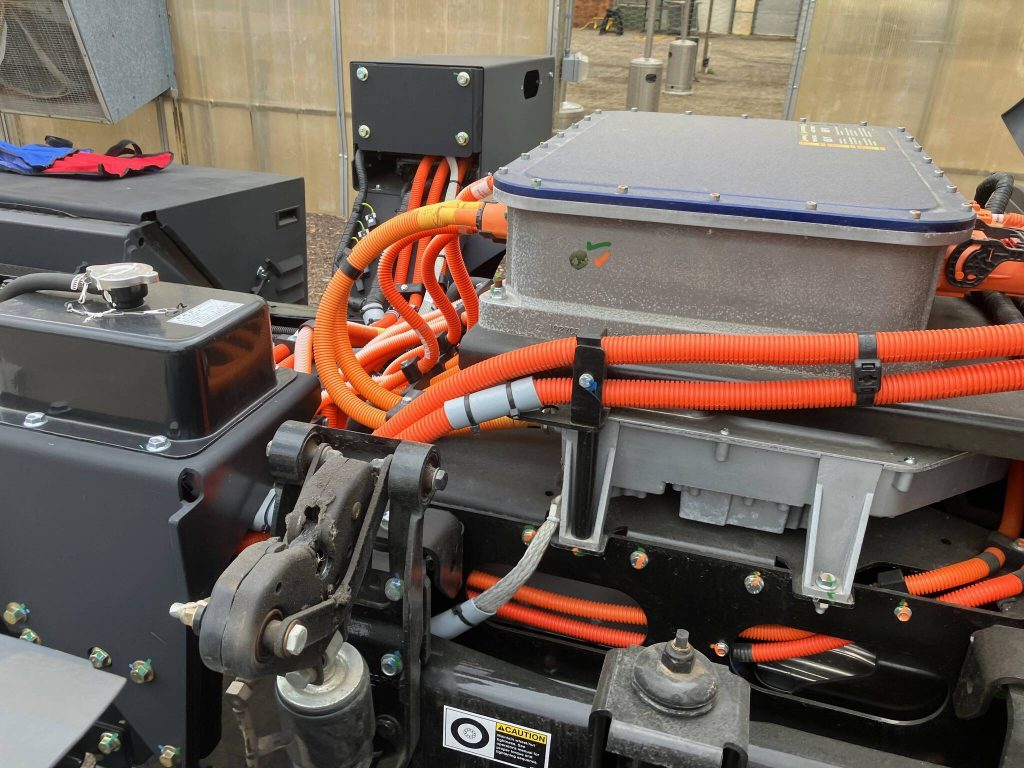

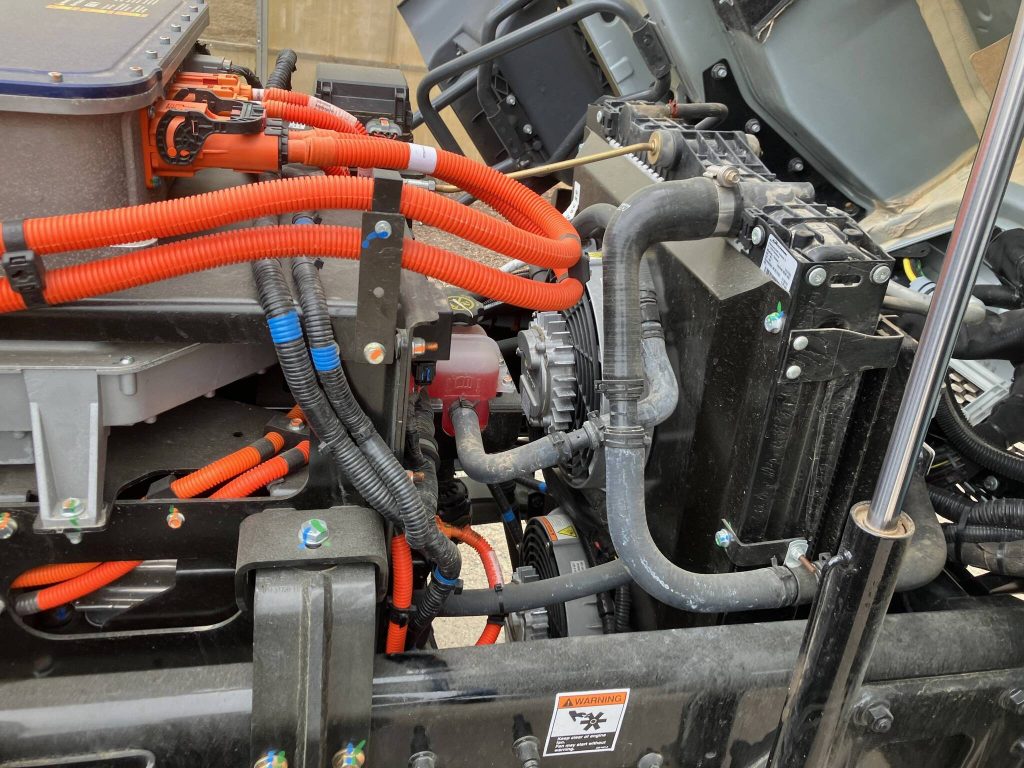

Fast forward to 2025. I find myself in the presence of a K270e at the Mass Fleet Advisor event at Lookout Farms. I had a brief but interesting chat with the sales people that were with the truck. It was just a cab & chassis with no body, which was fine for viewing the equipment. Aside from it being a handsome piece of equipment, I was troubled by the details. The wheelbase was LONG. I’m assuming this was the bigger battery version, but given the length, this truck would have some limited applications. It would need to be a 28′ or 30′ box, and though you could probably put a 26′ on it, the wheelbase would be wrong. That’s not uncommon on electric trucks. They fit a lot of gear under the body and need space, so short wheelbases aren’t easy. At 19.5k GVW, it’s easier to fiddle with sizing as it can replace a lighter truck if you need a smaller body and the axle weights can work out, and the truck is still a shorter wheelbase than your typical under CDL 24′ box truck. When a chassis is set up for that very long wheelbase you’ll need to be careful where you send it (at least it was a cabover). I think they could have packaged it differently, however. The way they organized the gear suggests both a lack of seriousness and a lack of progress from the initial prototype trucks.

The electric motor is placed way at the front of the truck where the automatic transmission would have been, which makes some things easier. They re-used the diesel’s long driveshaft and rear axle. This lost them ALL of the space between the frame rails, added a lot of parts, and increased weight. I get that the new e-axles are expensive, but they could have mounted the motor behind the real axle and flipped it (pusher configuration like a cement mixer or a tour bus), having a very short driveshaft and leaving the frame rails empty in the middle.

This setup forced them to put the batteries on the outside. I take a very dim view of this as it exposes them to side impacts which makes me very worried about resulting battery fires. You can armor them up, but this adds weight and complexity. The frame rails offer a very safe location and I think if a company is serious about safety, they’ll start with batteries between the rails first, and if they need more range only then look at outboard battery storage.

Final Thoughts

I think other solutions by other companies are much better (SEA/Hino/Mack, Bollinger, Isuzu) and this setup shows a real lack of innovation and imagination. It was the kind of arrangement I’d expect from someone building one in their backyard with limited access to resources. I confirmed it was a 2024 MY truck and I wonder if this is what they’re producing, what have they been doing for the past 5-10 years? Do they look at what other companies are making? Where do they expect to take this and are they learning anything from it? Given the resources PACCAR has, I find it all a bit disappointing.